ProX offers OEM quality connecting rod kits for less than the pricey manufacturers. Learn more about the manufacturing process and the parts included here.

Motorcycle and ATV engine builders may sometimes be suspicious of aftermarket replacement parts, especially for the critical rotating assembly. The connecting rod, for example, is one of the most tortured components in the engine. It’s compressed for half the combustion cycle and stretched during the other half. Taking a chance on replacing such an essential element of the engine with an inferior part is never in the best interest of a powersports enthusiast, so often the choice is to return to the dealership for an OEM part. However, there is an affordable alternative matching OEM quality.

“Some people feel more comfortable buying OEM than from the aftermarket,” says Matt Delfs of ProX Racing Parts. “We bridge that gap. We’re selling an OEM part but at a lower price.”

Find ProX connecting rods and many other parts for your application here.

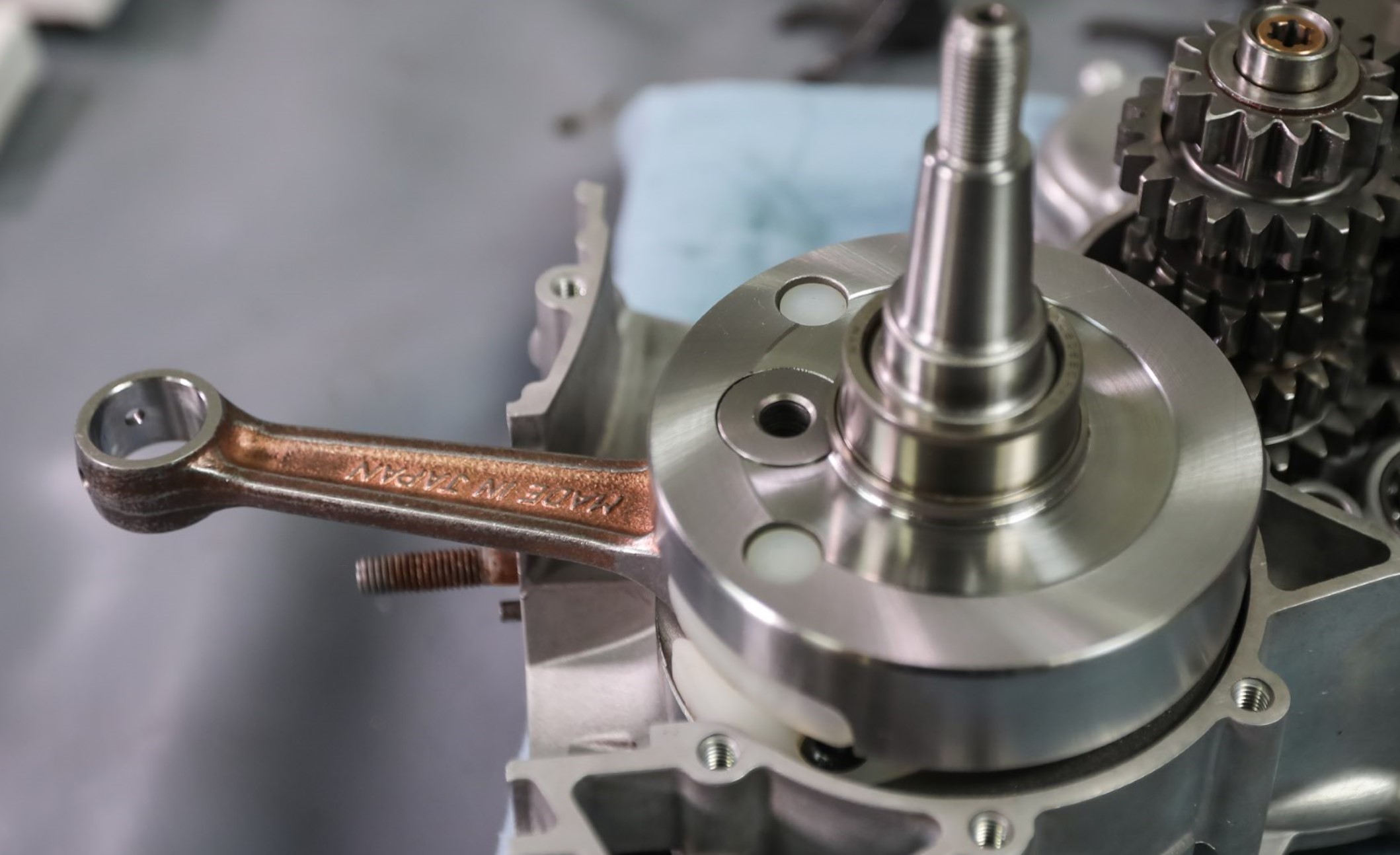

Complementary to ProX's complete crankshaft assemblies, ProX offers a complete line of replacement connecting-rod kits for dirt bikes, ATVs, personal watercraft and street bikes—all sourced from the same factories in Japan that supply the leading manufacturers. ProX connecting rod kits help fill those gaps for those who want to refresh their bottom with OE-quality parts without spending OEM parts money.

Plus, ProX has recently expanded their connecting rod offerings to cover newer model dirt bikes that come equipped from the factory with plain bearing-style big-end bearings. 'Plain bearing' refers to an automotive-style rod bearing that is simply two bearing shell halves that are affixed in the big-end of the rod. The crank pin fits into these bearing shells within OEM tolerances and rides on a film of oil between the pin and the bearing. ProX's plain bearings utilize German multi-metal technology with Tin plating, which, in combination with the plain bearing design, make them better equipped to handle higher engine loads and better resist bearing and pin wear.

.jpg?width=290&name=ProX20_rod1%20(1).jpg)

“It’s a double-forged steel rod made in Japan from Japanese steel. The market recognizes Japanese steel as very high quality,” confirms Delfs. “We’re supplying the same connecting rod as the OEM. It’s even from the same tooling, but with the ProX name.”

Find ProX connecting rods and many other parts for your application here.

The ProX connecting rods feature the same I-beam shape, dimensions and geometry as OEM equipment. Double forging means the raw steel alloy is hammered twice to ensure strength and consistency.

“When you forge, it aligns all the molecules and grain flow within the structure to line up with the features of the rod,” explains Delfs. “The grain will flow around the big end and the small end--it's all aligned within the structure to give it better strength. When you double forge, you hit it once and then again to align it even further.”

By using the OEM tooling, the connecting rod has the same accurate bore diameters at each end. This is essential to the fitment of new bearings that are supplied in the ProX connecting rod kits.

“The rod kit is complete. You generally can't buy it as a kit from the OEM, just the pieces,” adds Delfs. “All the components in the rod kit are from the same Japanese factories, including the bearing cages, the rollers, thrust washers and the big-end pin that assembles to the crankshaft halves.”

ProX provides flat-silver style cages for select high-output engines, such as those found in motocross and sport ATV engines. Also provided in the connecting rod kit is the big-end pin. They’re precision machined and heat-treated. The 4-stroke pins also include oil canals to maximize lubrication. Other key durability features of the connecting rod are the barrelling and shot-peening processes during manufacturing.

“The rods are heat treated, barrelled and shot peened to remove imperfections from the surface texture. It's critically important to the life of the rod,” explains Delfs. “Any sharp corners can turn into stress cracks that can eventually lead to failure.”

ProX also ensures proper lubrication by precisely locating the oiling slots and duplicating the OEM-style oiling pockets on the washers to reduce friction between the rod, washer and crankshaft web. “We include oil slots where it makes sense on the rod to enhance oiling to the bearings,” says Delfs. “Washers are available either copper or silver, based on the OEM recommendations. Both offer high surface lubricity qualities.”

ProX offers connecting rod kits for a wide variety of powersports applications, starting with popular models introduced in the ‘80s. Working with a respected machine shop, a DIY engine builder can cut costs by ordering a ProX connecting rod kit instead of getting a complete crankshaft assembly from the dealer.

“As the bearings wear out, so do the rods,” cautions Delfs. “When you press apart the crank assembly, you're going to want to put on all new components at that point. The beauty of a connecting rod kit over buying an entire crankshaft assembly is the cost.

“You buy the kit and have local machine shop handle the pressing,” sums up Delfs. “It's for the budget-conscious guy who wants the assured quality.”