Despite what gear heads might think, two-strokes are not dead. While manufacturers abandoned two-strokes for use in professional motocross racing a decade ago, there is a contingent of enthusiasts still clinging to their beloved ring-a-ding-ding machine. Add in the fact that KTM released a line of fuel-injected two-strokes last year, and it appears that there’s a groundswell of interest for this technology. Two-strokes are once again cool.

While two-strokes are coming back into fashion, ProX has never left the scene. The brand has remained committed to advancing two-stroke performance through technology by way of research and development. That, of course, costs a judicious use of funding. That’s admirable, given how four-strokes gobbled up market share. Most OEMs either halted two-stroke production or recycled aged designs. ProX has remained true to the course.

See ProX's complete parts lineup for the new YZ65 here.

The philosophy behind ProX Racing Parts’ pistons is that their piston quality and specs should meet or exceed the OEM level of quality. That is a very high standard. The majority of ProX two-stroke pistons are manufactured in Japan. All ProX pistons are designed and then machined under strict tolerances using the same factories as the big four Japanese manufacturers (Honda, Kawasaki, Suzuki and Yamaha).

Need help rebuilding your 2-stroke top end? We have a complete guide here!

Most of the ProX two-stroke pistons are made from castings, while only a few are forged pistons. In general, the cast piston is a great working solution for the two-stroke engine. Casting is relatively simple and also relatively cost efficient compared to a forged piston. The key is in using the right material. When done properly, casting offers a very stable piston. ProX two-stroke pistons are made through gravity casting using aluminum alloy with approximately 18 percent silicon content. Silicon plays a vital role in ProX’s cast piston manufacturing, as it decreases thermal expansion. A piston undergoes a severe amount of heat and stress when moving up and down at thousands of revolutions per minute while subjected to intense pressure and combustion. By lowering thermal expansion, the piston is able to maintain tighter tolerances, which translates into increased power. Silicon also has better wear characteristics, meaning a longer lifespan due to a result of lessening wear on the piston skirt.

In some market segments, ProX pistons are made of hypereutectic alloy. This specific type of alloy has a higher silicon content, which results in harder and stiffer piston construction. Another benefit is that it is even less sensitive to thermal expansion and/or deformation than standard Japanese piston alloys.

Need some tips on 2-stroke maintenance? Check out our guide here!

ProX piston designs are usually similar to the OEM/stock configurations, although sometimes these designs are adjusted whenever the ProX engineers discover an opportunity for increased performance. Lubrication is a key component in engine operation. To ensure that oil reaches the right areas of the piston, ProX has added specific lubrication holes in most of their pistons. These holes can be found in the pin bosses, which lubricate the piston pin. Holes are also added in the exhaust skirt in case the exhaust port of the cylinder is bridged.

ProX has found a brilliant solution for additional performance gains. By using various coatings, they can add benefits while maintaining a competitively priced piston. ProX has a variety of coating possibilities at their fingertips. The most commonly used coating is MOS2, which stands for Molybdenum Disulfide. This coating is applied to the piston skirt. Recognizable to most people by the black coloring, MOS2 functions as a break-in coating. This smoothens the surface of the piston skirt during the break-in process, leaving a perfect working area on the piston skirts. Not only that, MOS2 also helps reduce friction after wearing in. It is essentially insurance for effective piston skirt-to-cylinder interface.

Another common upgrade used is the Alumite coating inside the piston pin bore of the piston. Alumite coating smoothens the surface and leaves a hard and protective area in the pinhole. This protects against piston pin rocking.

With the introduction of fuel injection, sometimes engines run at much higher temperatures, meaning that pistons are facing more heat. To cope with this amount of heat, ProX has chosen to add a special dome anodizing. This anodizing is a hard layer of protection for the piston. Through the wonders of science, the special dome anodizing actually integrates with the piston alloy. The anodizing runs across the piston crown, including the first piston ring groove and pin holes, preventing hot gases from burning into the alloy. Note that some applications do not require anodizing, due to the fact that those specific engines may not run as hot. This does not mean that non-anodized pistons are inferior, only that the applications aren’t subjected to as much heat and so anodizing is not necessary. It should also be mentioned that ProX has reconfigured some piston designs on specific applications to utilize a two-ring layout. This aids in durability. In total, these coatings result in smooth and quiet engine operation, increasing the lifespan of the piston.

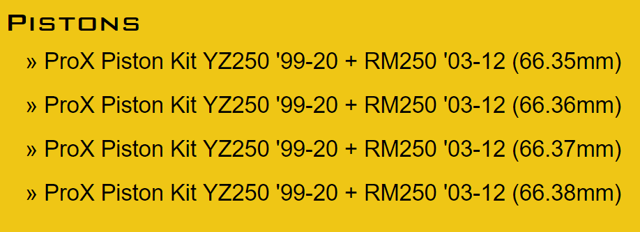

ProX two-stroke pistons are manufactured for both cast iron cylinder bores and Nikasil cylinder bores. For the cast iron cylinder bores, ProX usually offers a large variety of oversizes (from a standard bore up to 2mm oversize). In many cases, an OEM supplier may not even offer an oversize option, or if they do, jump straight to 1mm larger. With ProX’s multiple oversize options, it is possible to make full use of the cylinder material instead of having to buy an expensive new cylinder or sleeve job.

Regarding Nikasil cylinder bores, ProX offers a variety in oversizes graded in A/B/C/D sizing, each going up 0.01mm in diameter. With these graded piston sizes, the engine can always be set at the optimal piston-to-wall clearance. Thanks to several piston size options, riders can take advantage of fully using the Nikasil layer, rather than biting the bullet and coughing up money for an expensive replating job.

Piston rings are a very important part of the piston kit. Their job is to keep the combusted gases corralled, as well as transfer oil back to the crankcase and disperse heat from the piston to the cylinder wall. The better the rings seal, the more efficient the engine runs. That is how the most horsepower is made. ProX piston kits come with high-quality Japanese Rikken and TP rings, which are the benchmark in piston ring manufacturing. Note that ProX rings are designed to be used in cast iron bores, Nikasil bores, boron composite and electrofusion bores. Additionally, should the OEM cylinder have a chrome bore, ProX will supply a piston ring specifically for that application.

All ProX piston kits are complete with a piston, ring set, piston pin, circlips, and helpful instructions for installation. These kits cover ProX Racing Parts’ extensive line of two-stroke pistons for motocross, ATV, watercraft, snowmobile, and the 50cc/scooter markets. Find pistons and other parts for your machine at pro-x.com!