Make sure you follow these important prep tips for your snowmobile before you get out there this winter season.

These days, when you go shopping for a new snowmobile, you’re not quite sure what you’re buying. Don’t get me wrong, today’s sleds offer state-of-the-art technology, performance, comfort and handling unlike any other time in the history of snowmobiling. An unfortunate part of these premium sleds is the price tag that comes with many of them. However, this should not deter motorsports enthusiasts from entering the sport of snowmobiling and experiencing the beauty and thrills of riding in the backcountry during the winter months.

There is a huge selection of used snowmobiles at very affordable prices that are just over 10 years old, and are almost turn- key. For the mechanically inclined, there is an equal number ready for a rebuild, not to mention that the styling on many of the older sleds is timeless. For the first-time buyer, or those looking to grow their herd, the used snowmobile market is ideal. Whether you're picking up a new-to-you sled or just need to get yours ready after sitting for a while, we have some important tips to get you out on the trails.

Two stroke motors remain a relatively easy technology to dig into with a minimal mechanical background, allowing the garage mechanic the opportunity to rebuild a motor with limited specialty tools. But, where do you begin? Well, from racing and restoring snowmobiles, I soon learned my choice of machines was based on availability of parts and performance shops that can make the older motors run faster than many of today’s sleds, without experiencing “where’s Waldo” in looking for hard to find parts.

Ignition System and Top End

My biggest word of caution is to make sure your project has good spark. A dead ignition system can be a challenge to trouble shoot because electrical parts tend to become more scarce than other components under the hood. Beyond that, freshening up the top end with piston and gasket sets is common practice.

ProX Racing Parts offers piston kits for many older or classic machines, so when you start your research, you may want to start with what parts are currently available. ProX 2-stroke pistons are CNC machined from a Hypereutectic cast Aluminum alloy, which contains approximately 18% silicon, allowing for less thermal expansion during engine operation. Less expansion means tighter tolerances, which translates to more horsepower and smoother performance.

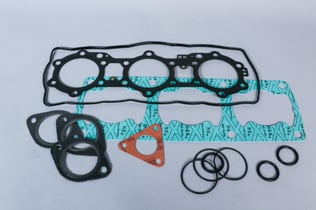

ProX snowmobile piston kits come complete with pistons, rings, wrist pins, circlips and easy installation instructions. All ProX parts are manufactured at or above OEM specifications, and many of them on the same equipment OEM parts are manufactured on. ProX also offers small end bearings and gasket kits to complete your top end rebuild.

If you need the crank rebuilt, many of the two stroke crank shops can still easily and affordably get all the necessary parts to rebuild the crankshaft.

Click for all ProX snowmobile parts.

Cleaning for Inspection

Once you have identified your parts program and procured your sled, the rebuilding process begins. If the sled runs, start it and get it warmed up (note, warmed up is just that, meaning, no need to overrun it). The next step is cleaning it, especially the motor. I’ve found that after you wash it, if you have trouble starting it, you’ll immediately know it’s allergic to water and you may have a seal leak or exposed electrical lines. Using an automotive degreaser, whether it’s a biodegradable or aerosol, a clean motor will allow you to inspect for areas that need special attention. Furthermore, if you have to tear the motor down, hopefully it will just be the top end, and the clean work environment will keep debris out of the case & crank.

Compression Test

With a clean motor, it’s now time to check the compression on your machine. The one nuance I’ve learned, and this comes from living at 9,200’ above sea level, is your altitude will give your compression tester a different reading, so allow yourself the standard variance, which should be about 3% for every thousand feet of elevation. For example, if you’re at 2,000’, your factor could be .094 against the factory rating. Typically, though, stock motors don’t begin to experience material variances until you start approaching +3,500’ above sea level.

With this particular tester, at over 9,000 feet in elevation here in the foothills of Colorado, this tester is showing more than 30% variance. At sea level, this reading should be around 120 psi to 140 psi which is sometimes driven by the quality of the gauge.

If the machine you’re prepping for the upcoming season is not new to you, but just getting the cover pulled off from last season, checking your compression is not necessary, unless you put it away in the spring with it not running it’s best.

Checking for Leaks

Going back to the motor, now is a good time to look for any leaks such as antifreeze or oil deposits. For water cooled motors, look for anti-freeze leaks coming from the head and cylinder gasket, manifolds between the heads or bleeder screws.

If during the cleaning process, you’ve noticed a lot of black oil in the belly pan or on the front of the motor, it may be time to replace the exhaust gaskets. This is a relatively easy task. Typically, there are two nuts per cylinder on the manifold. If they are loose, tightening them may not resolve the leak, but removing them, cleaning them, and applying some Permatex may be a good fix, again, outside of replacing them with new gaskets. And, while you’re near this end of the exhaust system, look for wear and tear on the fitting between the exhaust pipe and the exhaust manifold. If this seems loose, a good fix is to wrap the gap with some header pipe exhaust wrap, then use a hose clamp to hold the wrap in place as seen on this Free Air motor.

Wear Inspection

Moving to other parts of the sled, examine and clean your clutches. Check for slop between the weights and the weight pin. If just by twisting the weight on the pin you notice slop, just take an allenhead wrench and 3/8” wrench, remove the pin and look for wear marks on the pin. If you see grooves in the pin, you’ll need to replace them and most likely the weight – both are relatively inexpensive.

Also be sure to inspect the track, looking for excessive wear spots, and loose clips, studs or cleats, depending on the model and type of track. Finally, check the wearbars on the skis. This can easily be done by pulling the ski loop up and looking under the ski, or tipping the sled on its side. Most wear bars are around 3/8’ steel rod so anything beyond 70% wearing would indicate it’s a good time to replace them as the steering performance will suffer. I would also remove the chaincase, and check for wear and tear on the gears and chain, then change the chaincase oil.

Now, is this the complete pre-season ritual for every sled or snowmobile? No. But, it is a blueprint to become more familiar with your machine so the lack of simple of pre-season prep work doesn’t come back to bite you the minute you’re getting ready for your much anticipated first ride of the season. Again, it is always important to secure a shop manual for your machine, or consult your local dealer for any of the technical specs that are specific to your machine.

Have fun this winter, and stay tuned, literally.

Scroll down for more images.