Don't start your next riding season off with a broken bike. Check out these preventative maintenance tips to keep you on the track or the trail.

No matter where you are in the world, everyone usually has a motocross off season. It’s a time to kick off your boots and relax. Just like your body, though, your dirt bike or ATV needs a sufficient amount of recovery after the high demands and stress from the season. So before you decide to line up behind the gate again, it’s important to do a thorough inspection of some key components.

We contacted Dave Sulecki, Global Powersports Product Manager for ProX, and he offered some great advice. “Racing will always place higher demands on nearly all components of your engine and chassis,” explains Sulecki. “By carefully inspecting and replacing worn parts before they fail, you will always have optimum performance and eliminate the worry of a DNF. If you want to finish first, first you must finish!”

Photo: Brown Dog Wilson

Photo: Brown Dog Wilson

With that advice in mind, we compiled a list of the top five components to inspect and replace this off-season.

Drivetrain

It goes without saying that changing your oil and cleaning your air filter should be part of your regular maintenance and service. However, there are other key components that have a longer life and don’t require constant attention. One of the first things to check during this off season is your drivetrain. More specifically, your chain and sprockets. To determine if your chain needs to be replaced or not, simply add some tension to it by pinching the top and bottom together close to the countershaft. With your other hand, try to pull away the chain at the back end of your rear sprocket (three o’clock position). If the chain is able to pull away and you’re able to see the groves on your sprocket, your chain is stretched and needs to be replaced.

It’s a general rule of thumb that if you replace your chain, you need to replace both your front and rear sprocket at the same time, so the complete assembly wears together. Sulecki says, “As a chain wears, it begins to stretch in length, the distance between each chain roller becoming greater and greater. If this stretched chain is installed onto a new sprocket, the teeth of the sprocket cannot engage the chain rollers evenly, greatly accelerating the wear of the new sprocket teeth. The result is a new sprocket that is worn out in one short ride!”

The Fix

ProX offers both front and rear sprockets as well as chains for many motocross applications. The 420 and 520 MX roller chains are both designed specifically for motocross use and are made in OEM factories in Japan with OEM quality Japanese material. All of the materials used are heat treated to ensure high tensile and ultimate strength. X-Ring chains are also offered for certain applications, which feature a QX-type seal, resulting in less friction and more durability than a standard MX chain.

ProX front sprockets are manufactured from Ni-Chrome Molybdenum steel to keep corrosion and wear to a minimum. ProX rear sprockets are offered in both aluminum alloy and steel. Both versions are CNC machined for a solid fit and durability.

Check out ProX drivetrain products for your machine here.

Cam Chain

Your cam chain, or timing chain, is crucial to keeping your camshaft and crankshaft working in precisely timed, perfect harmony. However, when your cam chain becomes worn out, that can all come to a crashing halt, resulting in catastrophic damage to both your engine and your wallet. To prevent that from happening, an inspection needs to be done to assess its condition. After removing your bike’s valve cover, a similar test like for the drivetrain can be done to check the cam chain’s wear and tear. If there’s a lot of slop in the chain around the teeth of your camshaft, or the chain pulls away from the teeth, it’s time to replace. For a more accurate test, a simple pin-to-pin measurement comparing an old to a new cam chain will also tell you if it’s time to replace.

The Fix

Cam chains are relatively cheap, which should be an even better reason to replace it before it fails. ProX teamed up with Borg Warner, the main supplier to a variety of OEM companies worldwide, to manufacture a complete line of OEM quality cam chains at a better-than-OEM price.

Valves and Valve Shims

Valves play a key role in your engine’s performance. They allow the fuel and air mixture to come in through the intake valves, they seal compression, and then they allow burned gases to escape through the exhaust valves. However, when you’ve spent a season racing motocross, your valves see a great deal of stress. The high RPMs can wreak havoc on your engine, and shorten the life of your machine if you aren’t on top of your engine maintenance.

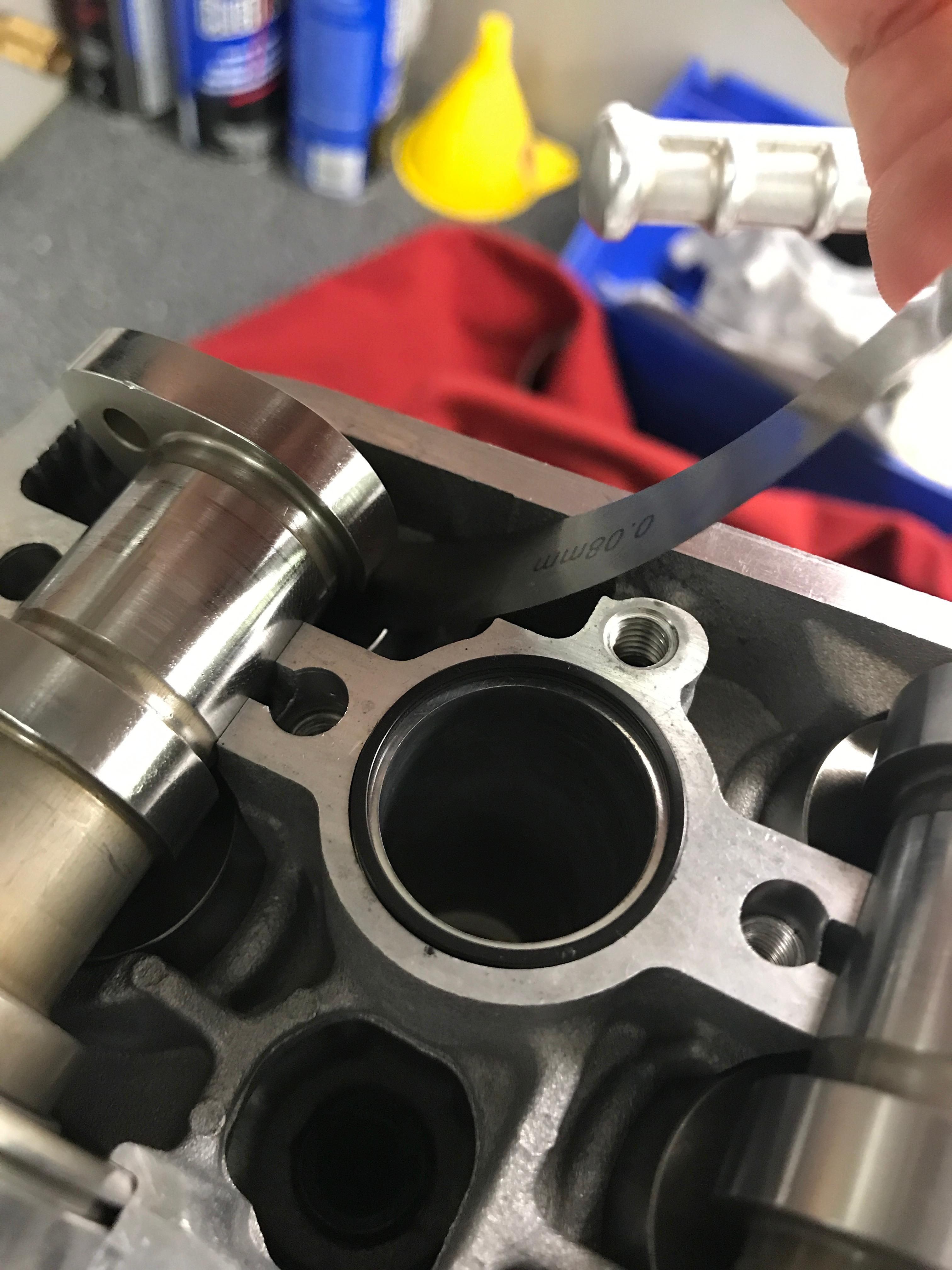

With your valve cover already off, now is the perfect time to check the clearances of each valve. Before you do so, though, make sure your engine is at top dead center (TDC). After you’ve properly lined up the marks on your engine for TDC, refer to your service manual for proper valve clearances, and then record each valve clearance on paper.

The Fix

If your clearances are off by a slight amount, it’s time to re-shim your valves. ProX offer shim kits with thicknesses ranging from 1.20 mm up to 3.50 mm by increments of 0.25 mm. However, if you’re making a big jump in shim size, there might be some damage done to your valves. By removing the cylinder head, you can inspect the valves for chips and cracks or excessive wear. If any are visible, they can be replaced with either ProX titanium or steel valves.

ProX steel valves are manufactured in the same factories as the Japanese OEM manufactures with the same steel, so they are a very cost effective OEM replacement. ProX titanium valves are individually machined from titanium forgings, and they are Chromium Nitride coated to exceed OEM surface hardness friction resistance. They are a premium choice above OEM parts.

Keep in mind, though, that there could be some damage done to your valve seat, requiring it to be recut or lapped. “A worn valve seat can destroy a new valve, wasting time and money,” explains Sulecki. “Depending on the hours on the valve train, it’s good to thoroughly inspect the valve seat for excess wear and potential leaking of a new valve. An engine with lower hours can normally receive a new valve and seal properly. Engines with steel valves can have the valve lapped to mate with the valve seat, depending upon the condition of the valve seat. Engines with titanium valves must have the seat recut if wear has destroyed the sealing surface. Do not lap titanium valves!”

See more information and ProX valve train component applications here.

Piston and Rings

Your piston and rings offer the essential job of providing an airtight seal in the cylinder and compressing the fuel mixture before it’s ignited by the spark plug. Worn out piston and rings will greatly reduce the overall performance of your dirt bike, and can cause a massive amount of damage if not inspected regularly.

That being said, before you re-install the cylinder head, it’s most likely time to replace your piston and rings. Most manufacturers recommend replacing your piston and rings every 40-80 hours, but under racing conditions, that recommended time is chopped down to every 15 hours.

The Fix

Sulecki says, “Tear down and inspection of your piston and rings is the best preventative maintenance that you can perform to your top end. Your OEM service manual will provide details such as piston to wall clearance, ring end gap, and general wear conditions that are important to performance. Generally speaking, piston rings will wear out before a piston, and sometimes replacing rings will restore performance provided the piston is still within specification.”

ProX offers complete piston kits for a wide range of applications and cylinders, and are all designed and developed to OEM specifications. Many ProX 4-stroke pistons have an OEM style tin coating, assisting with piston wear during the break in process. Many ProX 2-stroke pistons also have a skirt coating that reduces friction caused by contact with the cylinder wall during engine operation. ProX pistons are cast from Japanese quality alloy and CNC machined to OEM specs, as well as A, B, C, and D+ oversizes.

Check out ProX pistons and find the parts you need here.

Note: If your cylinder wall is scored, it will need to be honed to prevent further damage.

Clutch

Before you put everything back together and call it done, the final component we recommend checking is your clutch. Over the course of a season, your clutch can go through a lot of abuse, and one of the first signs of clutch wear is slippage. The fiber plates in your clutch pack will begin to wear out, and the loss of friction will dramatically decrease your speed, while shooting your RPMs through the roof.

The second sign is the smell. The smell of a burnt clutch is pretty distinct, making it easy to detect. If all of that isn’t enough, removal of the clutch cover will provide actual visual evidence: dark, discolored plates.

The Fix

If your clutch is in bad shape, it’s our recommendation that you completely replace the whole clutch pack and springs. ProX clutch components can be purchased as plates only all the way up to a complete clutch assembly replacement kit.

ProX fiber and steel plates are made to OEM specifications with the same materials as the OEMs, so they offer good wear resistance and performance and at an affordable price. ProX also offers clutch components that are an upgrade from stock. ProX clutch baskets and inner hubs are forged aluminum, offering much better strength and durability than stock cast parts, thanks to the feature aligned grain flow forging brings to aluminum. ProX clutch springs are also more resistant to fading and provide a better feel for the rider by featuring 10% increased stiffness over stock.

Find out more about available ProX clutch components here.